Alfamoly Coating (Molykote)

Alfamoly Coating (Molykote) Specification

- Type

- Alfamoly Coating (Molykote)

- Packaging

- Available in 1 kg, 5 kg, and 20 kg cans

- RoHS Compliance

- Yes

- Storage Conditions

- Store in a cool, dry place away from direct sunlight

- Solvent

- Hydrocarbon

- VOC Content

- <420 g/L

- Coverage

- Approx. 8-10 m²/kg at recommended film thickness

- Appearance

- Black dry film

- Binder

- Epoxy resin

- Corrosion Protection

- Excellent

- Density

- 1.13 g/cm³

- Shelf Life

- 24 months from date of manufacture

- Curing Time

- 30 minutes at room temperature; full cure at 200°C

- Film Thickness

- 10-20 microns

- Base Oil

- Mineral oil

- Coefficient of Friction

- 0.06 to 0.12 (dynamic)

- Color

- Black

- Application

- Anti-seize and dry lubrication for metal/metal interfaces

- Toxicity

- Non-toxic when cured

- Operating Temperature Range

- -180°C to +450°C (short term up to +600°C)

- Water Resistance

- Excellent

- Flash Point

- >24°C

- Adhesion to Metal

- Strong

Alfamoly Coating (Molykote) Trade Information

- Minimum Order Quantity

- 50 Square Foots

- Supply Ability

- 1000 Square Foots Per Month

- Delivery Time

- 7 Days

About Alfamoly Coating (Molykote)

ALFAMOLY is a specially bonded organic lubricant coating which contains solid lubricants like molybdenum di sulphide etc. Like Molykote, ALFAMOLY has the properties of anticorrosive and solid lubricity.

Crystal Structure of MoS2The function of a Lubricant is to separate the sliding surfaces sothat there will be no metallic contact of the mating components. Under normal load condition, oil and grease can capable of separating the metallic asperities contact. But under heavy load conditions, the socalled boundry lubrication occurs which permits asperities contacts with each other. On the other hand dry lubricants fill as well as cover the valleys and asperities to slide with each other sothat the mating asperities will be separated continuously for a long time.

PROCESS :

ALFAMOLY Coating is done by spraying, centrifuging, dipping processes. The surface of the components to be ALFAMOLY coated is prepared by the surface preparation processes like ALFANIT NITRIDING, phosphating, shot peening, glass bead blasting to have a surface finish of the level of 0.8 umm CLA. ALFAMOLY Coating can cover the asperities.

PROPERTIES:

The colour of the film is generally dark grey or black depending on the pigments used. Normaly with oil and grease with increse in load, the friction increases in between the mating components whereas with ALFAMOLY Coating the co-efficient of friction reduces when the load is increased and therefore the asperities donot contact but slides with each other.

ALFAMOLY Coating exhibit mainly galvanic corrosion resistance (the metal pair formation is avoided by introducing the nonconducting coating in between the galvanic cell forming metals) and fretting corrosion resistance(the worn out fine wear debries combines with atmospheric oxygen to form different oxides of iron along with volumetric changes ultimately ends up with seizure of the fits with complete destruction or premature failure due to the rapid fatigue of the components. )

ALFAMOLY Coating can be applied on steel, aluminium and its alloys, copper and its alloys etc.

Colletion of dust particles in normal conditions by the oil and grease media which develop the problem of scoring and connected failures is not available.

ALFAMOLY COATING being a physical deposit, failure due to wash out by water in components lubricated with grease can be avoided.

The coating thickness

The coating thickness can be from 25 to 75 umm and 25 umm thick coating is quite optional.

The corrosion resistance of ALFAMOLY COATING is superior than Cd, Zn, Cr, PLATING and PTFE Systems. ALFAMOLY Coated component withstands for more than 1200 hours when tested Asper ASTM 117 B and more than 2800 hours asper BS 9000 F3 on artificial weathering test. ALFAMOLY COATING shows excellent resistance to acids, alkalies, mineral oils etc.

ADVANTAGES:

ALFAMOLY COATING being a dry lubricant has very good corrosion resistance as compared to Zn, Cd, Ni, Cr plating processes.

It does not pick up dust particles like oil and Grease which develop the problem of scoring and connected failures.

It reduces the frictional torque.

It helps to dismantle the threaded components easily and for the parts to be dismantled very frequently.

It is effective and with high performance for the cutting tools by 60 - 150 %.

It reduces the expenditure on cutting tools by 40 - 50 % as against PVD/CVD Coatings.

It reduces the inventory cost of tools by 40 - 50 %.

It helps to reduce the damege of the surface of the components.

It helps for running in.

It can be applied on any type of steel, aluminium and its alloys, copper and its alloys etc.

Failure due to wash out by water in components lubricated with grease can be avoided by ALFAMOLY COATING .

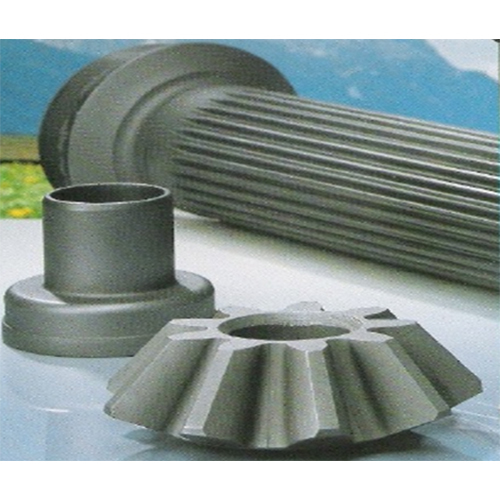

TYPICAL COMPONENTS :

- PETROCHEMICAL INDUSTRIES : Gate , Ball Valve and its components.

- ELECTRICAL INDUSTRIES : springs, spring washers, break assy leave springs, wheel pins.

- CONSTRUCTION EQUIPMENT INDUSTRY : Scaffolding eye bolts, Nuts, Tubular coupler, pin.

- TEXTILE INDUSTRIES : Slider, Spindle, guide bushes.

- PAPER INDUSTRIES : Valve spindles, Bushes.

- TYRE INDUSTRIES : Bearing shaft,tyre press bolt tyre matrix and mould release.

MATERIAL HANDLING EQUIPMENTS :

ELEVATED BUCKET PINS FOR CEMENT INDUSTRIES & MINING

Industrial Heavy Duty Chains,

Rollers, bush, pin etc. used in food, steel plants, cement, fertilizer industries.

Elevated Crane Pins,

Bearings and bushes for earth moving machines,

Bearings and bushes for conveyors.

AUTOMOBILE INDUSTRIES :

V Blocks, Dynamo shafts, bushes,

Threaded parts etc

Tower Spindles,Shafts,

Beaings, Gas Cylinder Threaded parts,

Slide ways, Sliding guides,Chain Parts,

Photographic Camera parts,

Crane pins, high torque bolts, screws, pins and nozzles for spray guns,

Moving jaws and jaw guides of chuck etc.

Exceptional Corrosion and Water Resistance

Alfamoly Coating (Molykote) is specially formulated to provide excellent protection against corrosion and water ingress. Its robust film ensures reliable performance in harsh environments, safeguarding metal surfaces and extending the life of critical components. Suited for industrial and outdoor applications, its water-resistant properties prevent moisture-related damage.

Reliable Metal-to-Metal Lubrication

Engineered to reduce friction with a dynamic coefficient ranging from 0.06 to 0.12, Alfamoly Coating ensures smooth operation and minimizes wear between metal parts. Its strong adhesion to metal surfaces delivers consistent lubrication, even under high temperatures and demanding service conditions. This makes it a preferred solution for anti-seize protection in a range of mechanical assemblies.

User-Friendly Application and Storage

With easy application and a quick room-temperature curing time of just 30 minutes (full cure at 200C), Alfamoly Coating streamlines maintenance routines. Its shelf life of 24 months and non-toxic, RoHS-compliant formula underscore both user safety and environmental responsibility. Store in a cool, dry place, away from sunlight, for optimal longevity.

FAQ's of Alfamoly Coating (Molykote):

Q: How should Alfamoly Coating (Molykote) be applied for optimal performance?

A: For best results, apply a thin, even layer of Alfamoly Coating to clean, dry metal surfaces. Recommended film thickness is 10-20 microns, which provides optimal coverage of approximately 8-10 m2/kg. Allow 30 minutes to cure at room temperature or fully cure at 200C for enhanced durability.Q: What are the primary benefits of using Alfamoly Coating as a lubricant?

A: Alfamoly Coating offers outstanding anti-seize performance, strong adhesion, excellent water resistance, and reliable corrosion protection. Its wide temperature range and durable dry film minimize friction and wear, ensuring equipment longevity and hassle-free maintenance.Q: When is Alfamoly Coating most effectively used?

A: This coating is most effective for anti-seize and dry lubrication in metal-to-metal interfaces, especially in environments exposed to moisture, high temperatures, or the risk of corrosion. It is suitable for both preventive maintenance and long-term equipment protection.Q: Where can Alfamoly Coating be stored and what are the storage guidelines?

A: Store Alfamoly Coating in a cool, dry location away from direct sunlight to preserve its shelf life, which is 24 months from the date of manufacture. Proper storage ensures the product maintains its chemical stability and performance characteristics.Q: What is the process for curing Alfamoly Coating after application?

A: Once applied, the coating air-dries in about 30 minutes at room temperature. For a complete and fully hardened film, a thermal cure at 200C is recommended, further enhancing adhesion and the protective properties of the coating.Q: Is Alfamoly Coating environmentally friendly and safe to use?

A: Yes, Alfamoly Coating is RoHS compliant and non-toxic once cured. It has a VOC content of less than 420 g/L and is designed for safe handling in industrial and maintenance settings when used as directed.

- Minimum Order Quantity

- 50 Square Foots

- Supply Ability

- 1000 Square Foots Per Month

- Delivery Time

- 7 Days

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email