Copper & Alloys Heat Treatment Services

Copper & Alloys Heat Treatment Services Specification

- Temperature

- Room Temperature to 1100C

- Application Areas

- Annealing, Stress Relieving, Tempering, Hardening, Solution Annealing of Copper & Alloys

- Terminal Type

- Screw / Lug / Customized

- Diameter

- As per Customer Specification

- Mounting Type

- Floor Mounted / Pit Type / Lift-off Type

- Heating Element

- Kanthal / Nichrome / Silicon Carbide

- Features

- Accurate Temperature Control, PLC/SCADA Automation, Data Logger, Uniform Heating, Safety Interlocks

- Usage

- Industrial Heat Treatment of Sheets, Rods, Tubes & Components

- Voltage

- 220V / 380V / 415V (as per Plant Requirement)

- Phase

- Single & Three Phase

- Frequency

- 50Hz / 60Hz

- Material Specified

- Copper & Copper Alloys

- Insulation Material

- Ceramic Fiber / Mica / Mineral Wool (as applicable)

- Shape

- Customized as per Job / Component

- Power

- Electronic / Gas / Oil based (as per process need)

- Control Panel

- Digital / PLC based with Alarm System

- Service Mode

- Onsite / In-house

- Quenching Medium

- Water, Oil, Polymer, Air (as per process)

- Surface Finish Capability

- Bright Annealing Possible

- Maximum Load Capacity

- Customizable up to several Tons

- Process Atmosphere

- Air / Protective (Nitrogen, Argon, etc.)

- Furnace Type

- Batch, Continuous, Bell, Pit, Conveyor

- Batch Size

- Small to Large-scale Production

About Copper & Alloys Heat Treatment Services

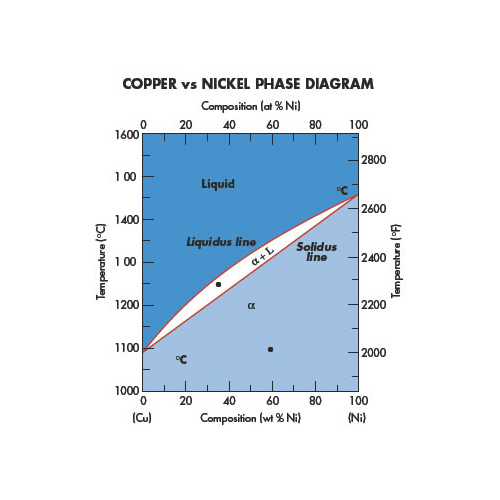

Copper is one of the most useful metals known to man, and it was one of the first to be utilized. Copper is a reddish-yellow material and is extremely ductile. Copper has a face-centered-cubic (fcc) crystal structure and has the second best electrical conductivity of the metals, second only to silver compared to which it has a conductivity of 97%. There are as many as 400 different copper and copper-alloy compositions loosely grouped into the categories: copper, high copper alloy, brasses, bronzes, copper nickels, coppernickelzinc (nickel silver), leaded copper, and special alloys.

Heat treatment of copper alloys involves several processes to enhance their properties such as strength, ductility, and electrical conductivity. Here are the main heat treatment techniques used for copper alloys:

1. HOMOGENISING

Purpose : To dissolve and absorb segregation and coring found in cast and hot-worked materials.

Process : Heating the alloy to a high temperature for an extended period.

Applications : Commonly used for tin bronzes, silicon bronzes, and copper-nickels.

2. ANNEALING

Purpose : To soften the metal, improve ductility, and relieve internal stresses.

Process : Heating the material to a specific temperature and then cooling it slowly.

Applications : Used for cold-worked metals to induce recrystallization and grain growth.

3. STRESS RELIEVING

Purpose : To reduce residual stresses in the material without significantly altering its mechanical properties.

Process : Heating the alloy to a lower temperature and then cooling it slowly.

Applications : Used after cold working or welding to prevent distortion and cracking.

4. PRECIPITATION HARDENING (AGE HARDENING)

Purpose : To increase the strength and hardness of the alloy.

Process : Solution heat treatment followed by aging at a lower temperature.

Applications : Used for alloys like beryllium copper, which gain strength through the precipitation of fine particles within the metal matrix.

5. SOLUTION HEAT TREATMENT

Purpose : To create a homogenous structure by dissolving alloying elements.

Process : Heating the alloy to a high temperature and then quenching it rapidly.

Applications : Used for alloys that require uniform distribution of alloying elements.

These heat treatment processes help tailor the properties of copper alloys for specific applications, such as electrical conductors, automotive parts, and construction materials.

Comprehensive Copper & Alloy Heat Treatment Solutions

We specialize in a wide array of heat treatment processes tailored for copper and copper alloys. Our services are designed for industries needing precise thermal management-be it stress relieving, hardening, tempering, or annealing. Using state-of-the-art furnaces and controls, we deliver uniform, reliable outcomes with efficiency and safety. Our customizable solutions accommodate small batch runs to large-scale productions, ensuring material integrity and performance.

Advanced Process Capabilities and Flexible Operations

With the capacity to operate using air or protective atmospheres (nitrogen, argon, etc.), we can optimize treatment for multiple applications. Quenching mediums can be selected as water, oil, polymer, or air, catering to customer and process specifications. Our system boasts PLC/SCADA automation, data loggers, and robust safety interlocks, allowing precise process management and traceability. We process components in various shapes and custom dimensions, ensuring comprehensive service for diverse industry needs.

FAQ's of Copper & Alloys Heat Treatment Services:

Q: How is the heat treatment process for copper and its alloys tailored to my specific application?

A: We customize each process based on your component's material, shape, and required properties. Our team selects the appropriate furnace type, process atmosphere (air, nitrogen, argon), quenching medium, and heat cycle to optimize your results-whether for annealing, hardening, or stress relieving.Q: What are the benefits of using protective atmospheres during heat treatment?

A: Protective atmospheres like nitrogen or argon help minimize oxidation and surface discoloration, enabling bright annealing and preserving surface quality. This is especially beneficial for components requiring high conductivity and aesthetic finishes.Q: Where are your heat treatment services available and do you offer onsite support?

A: Our services are available across India. We offer both in-house processing at our specialized facilities and onsite treatment, depending on the size and requirements of your project.Q: What is the maximum load and batch size you can process at once?

A: Our facilities are equipped to handle loads up to several tons. We can accommodate small test batches as well as large-scale industrial production, providing flexibility for different business needs.Q: Which heat treatment applications can you perform for copper and its alloys?

A: We specialize in annealing, stress relieving, tempering, hardening, and solution annealing. Our process capabilities support sheets, rods, tubes, and custom components, ensuring versatility for varied industry applications.Q: How do you ensure precise and uniform heating during the process?

A: We use advanced digital and PLC-controlled panels with accurate temperature control, data loggers, and uniform heating systems. Our furnaces are designed to maintain stable thermal conditions, ensuring repeatable high-quality results.

- Minimum Order Quantity

- 1 Unit

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+