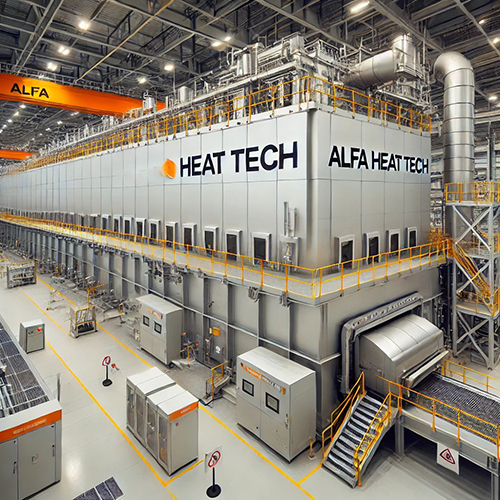

Heat Treatment Furnaces

Heat Treatment Furnaces Specification

- Feature

- High Quality

- Condition

- New

- Usage

- Heat Treatment furnace

- Voltage

- 200-450 Volt (v)

- Warranty

- 5 Years

Heat Treatment Furnaces Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Heat Treatment Furnaces

Heat treatment furnacesare essential in various industries for altering the physical and sometimeschemical properties of materials, typically metals. AHT manufacture thefollowing types of furnaces.

Types ofHeat Treatment Furnaces

Batch Furnaces: Used for treating small quantities of materials.Examples include box furnaces, pit furnaces, and bell furnaces.

Continuous Furnaces: Designed for large-scale production. Examplesinclude belt furnaces, roller hearth furnaces, and pusher furnaces.

Vacuum Furnaces: Used for processes requiring a controlled atmosphereto prevent oxidation.

Salt Bath Furnaces: Utilize molten salt to achieve uniform heating andcooling Process

Heating: The material is heated to a specific temperature toachieve the desired properties.

Soaking: The material is held at the target temperature for aperiod to ensure uniform treatment.

Cooling: The material is cooled at a controlled rate toachieve the desired hardness andstrength.

Benefits

Improved Mechanical Properties: Enhances hardness, strength, and ductility.

Stress Relief: Reduces internal stresses in the material.

Microstructure Refinement: Improves the grain structure of the material.

Applications

Automotive Industry: Used for engine components, gears, and othercritical parts.

Aerospace Industry: Essential for treating high-performance alloys.

Tool and Die Industry: Used for hardening and tempering tools and dies.

Price 350.0 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+