Specification

- सामग्री संरचना%

- Nitrogen 0.6–1.2%, Carbon 0.15–0.25%

- व्यास

- As required

- ऊष्मा प्रतिरोध

- Yes

- पुन: उपयोग करने योग्य

- Yes

- संक्षारण प्रतिरोधी

- Yes

- साइज

- Custom options

- टेन्साइल स्ट्रेंथ

- Approximately 700–1100 MPa

- कठोरता

- 550–700 HV (Vickers Hardness)

- कोटिंग का प्रकार

- None (Diffused case)

- उत्पाद प्रपत्र

- Component/Part

- प्रोडक्ट का नाम

- स्टील का प्रकार

- स्टील उत्पाद का प्रकार

- ग्रेड

- Industrial

- मोटाई

- As specified

- शेप

- स्टील स्टैंडर्ड

- सतह

- Case-Hardened

- रचना

- Iron with enriched Nitride and Carbon

- एप्लीकेशन

- आयाम (एल* डब्ल्यू* एच)

- Customizable

- वज़न

- As per requirement

- रंग

- Grey/Black

- सामग्री ग्रेड

- Industrial/Engineering

- फ़िनिश टाइप

- Smooth, Diffused Case

- उपयोग

- Wear and corrosion-resistant surface engineering

- Production Capacity

- High-volume batch

- Treatment Process

- Gaseous Ferritic Nitrocarburizing (GFNC)

- Surface Roughness

- ≤ Ra 1.6 μm (after process)

- Compatibility

- Suitable for gears, automotive parts, hydraulic components

- Process Duration

- 2–8 hours depending on application

- Custom Solutions

- Available on request

- Base Material

- Alloy Steel, Carbon Steel, and Cast Iron

- Environmental Compliance

- Eco-friendly gas process

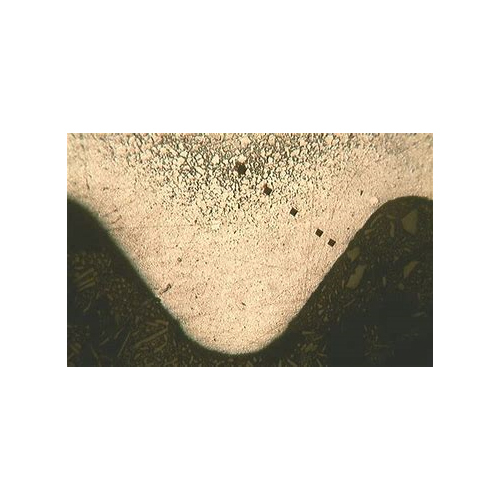

- Case Depth

- 0.25–0.60 mm

- Service Temperature Range

- Up to 600°C

- Delivery Condition

- Finished, ready to install

- Main Features

- Improved wear resistance, reduced friction, high surface hardness, resistance to tempering

Trade Information

- Minimum Order Quantity

- 50 Kilograms

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About

Gaseous ferritic nitrocarburizing is also known as controlled nitrocarburizing, soft nitriding, and vacuum nitrocarburizing or by the tradenames "UltraOx", "Nitrotec", "Nitemper", "Deganit", "Triniding", "Corr-I-Dur", "Nitroc", "Nitreg-C", "Nitrowear", and "Nitroneg". The process works to achieve the same result as the salt bath process, except gaseous mixtures are used to diffuse the nitrogen and carbon into the workpiece.

The parts are first cleaned, usually with a vapor degreasing process, and then nitrocarburized around 570 oC (1,058 oF), with a processing time that ranges from one to four hours. The actual gas mixtures are proprietary, but they usually contain ammonia and an endothermic gas.

In comparison to a standard nitriding process, ferritic nitrocarburizing or FNC in a vacuum furnace takes less time to achieve case depth requirements - mainly in part due to the addition of carbon to achieve faster diffusion.

Precision Surface Hardening Solution

GFNC provides a case-hardened surface that dramatically increases wear and corrosion resistance without altering the base materials core properties. The process is ideal for high-stress industrial components requiring enhanced surface performance, including gears, hydraulic parts, and automotive assemblies. Finished products exhibit uniform hardness, a refined finish, and improved longevity across a broad range of operating conditions.

Environmentally Conscious and Efficient

This eco-friendly gas-based process ensures that components achieve the required surface properties with minimal environmental impact. The treatment is conducted at controlled temperatures (up to 600C) in batch processes, supporting high-volume production and custom solutions for a variety of steel grades. Components are delivered ready to install, reducing lead times and streamlining your supply chain need.

FAQs of Gaseous Ferritic Nitro Carburising:

Q: How does Gaseous Ferritic Nitro Carburising (GFNC) improve component performance?

A: GFNC enhances surface hardness, wear resistance, and reduces friction by diffusing nitrogen and carbon into the base materials outer layer. This produces a tough, wear-resistant case while retaining core toughness, making it ideal for applications requiring extended service life and reliability.Q: What base materials are suitable for the GFNC treatment process?

A: The process is suitable for alloy steel, carbon steel, and cast iron components that comply with industrial AISI standards. Custom dimensions and weights can be accommodated as per application requirements.Q: When is Ferritic Nitrocarburising typically performed during manufacturing?

A: GFNC is usually applied after the component has been machined to its final shape but before final installation or use. This ensures optimal surface hardening without affecting dimensional accuracy.Q: Where is GFNC best utilized within industrial applications?

A: GFNC-treated parts are especially useful in sectors like automotive, construction, and hydraulics, where parts such as gears, shafts, and hydraulic pistons require high wear and corrosion resistance under demanding operational environments.Q: What does the GFNC process involve and how long does it take?

A: The process involves exposing components to a controlled gaseous atmosphere at 520600C for 28 hours, depending on the required case depth and application. The nitrogen and carbon diffuse into the surface, creating a hardened, finished layer of 0.250.60 mm.Q: How should GFNC-treated components be used, and what are their main benefits?

A: Once treated, GFNC components are delivered finished and ready for installation. They offer improved surface integrity, enhanced resistance to corrosion and tempering, high hardness, and low friction, leading to reduced maintenance needs and a longer operational life.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+