Plasma Nitriding

Plasma Nitriding Specification

- Usage

- Industrial

- Size

- Standard

- Voltage

- 220-240 Volt (v)

- Warranty

- 1 Year

Plasma Nitriding Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1000 Kilograms Per Month

- Delivery Time

- 7 Days

About Plasma Nitriding

Plasma nitriding is defined as a lownitriding potential type process leading to the formation of thin compound layers in steelsPlasma Ion Nitrding is timely best technology for Low Alloys like EN19 EN 24 Steel

Plasma Nitriding Engineering Considerations

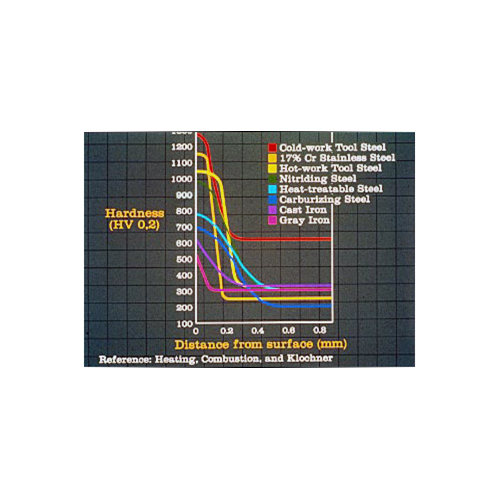

The plasma nitriding process produces a hard outer skin on the material being nitrided The hardness achieved on the surface decreases with depth until the core hardness is reached The graph shows the expected hardness for the various alloys at different case depths The slope is more gradual for low alloy steels and very sharp for highly alloyed steels The nitride forming elements in the steels composition are the primary factors controlling the hardness and the case depth The low alloy steel will provide a deeper case depth but a lower overall hardness

The micrograph shows a 400 series stainless steel alloy that has been plasma nitrided The high alloy content of the stainless steel creates a high surface hardness and a sharp transition zone between the nitrided surface and the core material A low alloy steel such as 4140 would have a lower overall surface hardness and a gradual transition zone between the nitrided layer and the core material however the overall penetration of the nitride layer would be deeper This is particularly useful when the product is subjected to impact or severe loading

The microstructure shows a 400 series stainless steel alloy that has been nitrided to improve its wear and fatigue properties

ADVANTAGES DISADVANTAGES OF NITRIDING

ADVANTAGES

Negligible Distortion Low temperature treatment 350 C to 550 C

High surface hardness All Nitrides has high hardness

High wear resistance coupled with antigalling properties

Improved Fatigue resistance

Better Creep resistance can withstand up to 500 C

Enhanced corrosion resistance

DISADVANTAGES

Very long duration ie 24 to 60 Hrs 1 day to 5 days

Formation of brittle white layer

Limited Control on repeatable results

Plasma Nitriding shortens the process 6 to 18 Hrs avoiding the brittle white layer formation and enhances all the properties of Nitriding with Repeatable and accurate results

Abrasion Resistance

Wear of moving parts in greatly reduced surface lubricity in enhanced Optical services life for steel groups which fit your process can be achieved Avoids production downtimes

Improve Fatigue Strength

Studies have shown fatigue strength is improved without distortion as compared to other surface treating methods due to increased compressive stresses at the surface fatigue strength is improved 40100 depending upon material and parts design Usually no post heat treat machining is required

Precise and Versatile

Aerospace Companies work in an unforgiving environment Lack of precise treatment could lead to disaster Todays Aerospace contractors are relying more and more Plasma Ion Nitriding for satisfactory performance of their vehicles

Non Polluting and Cost Effective

On top of the above added advantages no toxic salts Ammonia or other toxic gases are used in this process It requires less energy and utility cost

Ion Plasma Nitriding Pros

Mechanical masking sometimes reusable can be used to prevent nitriding of specific areas of the product

Great process for alloy steels and stainless steels that require surface activation to allow for nitriding

Ion bombardment helps sputter clean the surface

Gases used for processing are safe and environmentally friendly

Can be used for powder metals and titanium

Ion Plasma Nitriding Cons

Limited on compound zone thickness maximum due to the nature of the process

Relatively less superior temperature control as compared to gas this can lead to variance in case depth hardness dimensional stability

Increases surface roughness

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1000 Kilograms Per Month

- Delivery Time

- 7 Days

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email